Official Match Ball Pro League 2023-2025

Cannot ship to ()

Store Availability

This product is currently unavailable for your region

Please select a size

Store Availability

BENEFITS

Bounce

Bounce that meets the requirements of international football standards.

Ball touch

Foamy ball with a grip that promotes ball control and feel.

Robustness

Thermobonded construction with a laminated bladder for optimum robustness.

Lasting air retention

Guaranteed to keep ball pressure for longer thanks to the laminated rubber bladder.

Stable flight

Exclusive design with 12 grooved PU microfibre panels.

TECHNICAL INFORMATIONS

KIPSTA, SUPPLIER OF THE OFFICIAL PRO LEAGUE BALL FOR THE 2023-2024 SEASON

Kipsta, Decathlon's football brand, will be the official ball partner of the Pro League from the 2023-2024 season onwards.

Decathlon and the Pro League have reached an agreement for 5 years for the Jupiler Pro League, 1B Pro League, Croky Cup and the Supercup.

All of these competitions will be played with a Kipsta match ball.

DECATHLON will also become a structural partner of the Pro League's Football & Community activities.

Why this ball?

Thermobonding technology is used to make this ball.

This football was designed for the world of professional football. It reflects our expertise and meets the expectations of the most demanding players (players and goalkeepers).

It offers a heightened playing sensation thanks to its textured microfibre component with foam and grooves.

This football has an exclusive Kipsta design

What makes it special?

We've designed a ball with good reliability and stability of trajectory.

Our design choices were made with this in mind.

“What matters most about a football is that you're able to put it where you want it every time. Consistency above all else” Harry Kane.

Designed in France

This ball, just like the whole of our range, is 100% designed in France, and has been rigorously tested by a combination of lab and field tests. So it meets the strictest standards and requirements, as well as complying with a whole range of additional tests, specifically developed by Decathlon.

Apart from normative tests, our Kipsta Certification Unit carries out additional tests, that enable us to design, but also objectively compare our products.

Made in ... ?

Our balls are produced by our industrial partners in Asia (Pakistan and China for this ball).

Pakistan is known and recognised as the football ball capital of the world.

More than 50 years of quality craftsmanship, accompanied by a common commitment (with Decathlon), to 2 main points: respect for workers.

Last of all, we are working to identify future French or European industrial partners.

WHAT IS THE KIPSTA CERTIFICATION TEAM?

The Kipsta certification unit is a team made up of qualified field trial engineers, renowned for: establishing specific protocols and tests relating to how the products will be used.

Recruitment of qualified testers with a level suitable to evaluate products' functions.

Objective analysis of results, using statistical tools.

These tests cover general aspects, such as robustness, robust inflation, and functions that reflect the ball's technical aspects.

The Kipstadium, in Tourcoing, France

To design our balls, we have a dedicated team, as well as a laboratory based in France. The Ball team in France is made up of product engineers, component engineers and test engineers, which means we are able to master the entire ball design process, from components to technical validation.

Our ball lab

At Decathlon we've been testing our balls for over 15 years in order to validate our products during the design, industrialisation and post-production phases. A laboratory 100% dedicated to ball tests was even created in 2018 at the Kipstadium site in France.

More than a dozen tests are carried out on our balls. First of all, there are the tests required by FIFA, as well as other, additional tests, created by the engineers within our laboratory.

Decathlon, the designer

With 40 years' experience as a designer, Decathlon bases its product development on desirability and accessibility for all, consequently implying a notion of universality in their design (age, gender and nationality).

The group's, and therefore Kipsta's, aesthetic line is a balance between our convictions (simple, technical and clever products) and our sober, universal and modern artistic direction.

Designers as well as engineers

The DNA worked into this ball (i.e. the formal basis on which a graphic design is juxtaposed) combines technicity and balance.

The spatial apprehension and the visual effects linked to the ball during its movements are worked on so as not to cause any visual discomfort to the players, thus supporting the design choice.

Our industrial partners

We can count on the competence of our industrial partners.

We have strong commitments to our suppliers and production sites, so we can produce with confidence. These commitments, shared between Decathlon and our suppliers, focus on two main points: respect for workers.

Our industrial management provides us with efficient and reliable components and production solutions.

Every ball is checked just before being shipped

To ensure optimal quality for our official balls, they will be checked one by one (100% of production) at the end of the production line, in order to guarantee the quality of the latter just before shipment.

The quality control at the end of the production line will involve checking that the technical specifications relating to the ball have been met.

In addition, production samples will be taken regularly for further destructive testing.

An exclusive Kipsta design

We know that, in matches, the little details make all the difference. For this football, we wanted to create an ultra-reliable ball. We focused on the stability and feel of the ball in play. To do this, we tested different types of outer panelling and chose the one which showed the best results. This 12-panel design combined with the embossed lines is exclusive to Kipsta.

A beach ball?

We know that a stable trajectory is important, especially for field players kicking long balls and for goalkeepers sending the ball down the pitch. Traditionally designed using 32 panels, we've designed this ball using 12 identical panels. These 12 panels are also thermobonded and have special grooves in them, along with a microfibre fabric. This significantly improves the ball's stability and makes it more enjoyable to play with.

Did you say FIFA Quality Pro?

We conducted numerous lab tests on the ball in order to accurately meet the requirements of professional football. Each test is outlined below.

Too light? Too heavy? The weight is standardised...

This ball weighs between 420 g and 445 g (size 5) and complies with official FIFA standards.

FIFA Quality Pro ball.

How big is it? What's the circumference?

This ball measures between 68.5 cm and 69.5 cm (size 5) and complies with official FIFA standards.

FIFA Quality Pro ball.

A "round" ball?

Here's how we test sphericity:

Average measured variation: 1.5% max (FIFA Quality Pro standard).

We measure the football's sphericity at 4500 different points and then examine any differences.

When the discrepancy is greater than 1.5% (FIFA Quality PRO Standard), our engineers are tasked with improving the sphericity to ensure consistent rebound.

Maximum pressure loss test: here's what we do...

Here's how we test pressure loss: We inflate the ball to the recommended pressure (meaning 0.8 bar).

72 hours later, the ball must not have lost more than 15% of its pressure, meaning approx. 0.1 bar (FIFA QUALITY PRO certification). The pressure after 72 hours must, therefore, be at approx. 0.7 bar.

This also means that it is quite normal for a ball to lose pressure after a few days.The pressure recommended for the ball is 0.8 bar (1.0 bar max; 0.7 bar min).

We've also tested how much water the ball absorbs...

Here's how we test water absorption:

We simulate rainy playing conditions in a lab, leaving the ball to sit in 2 cm of water on a pivoting support whilst subjecting it to 250 compressions.

At the end of the test, the ball must have absorbed no more than 10% of its weight (FIFA Quality Pro standard). This is one of the advantages of the thermobonded process; water absorption is limited in comparison to other processes (machine-stitched for example)

It's all about the bounce

Here's the bounce test:

The ball is dropped onto a steel plate 10 times from a height of 2 metres.

The bounce height must be between 135 and 155 cm with a maximum difference of 10 cm between the ball's highest and lowest bounce.

Not even a scratch!

The most stringent test we put this ball through is the shooting machine test.

The ball must resist up to 2500 shots against an inclined flat concrete slab at 50 km/h at a distance of 2.5 m.

At the end of the test, we check:

- the ball's general state: stitching must withstand this test

- the circumference: must not have increased by more than 1.0 cm.

- the sphericity: it must not have varied by over 1.5%

- the pressure: loss of pressure must not exceed 10.0%.

How about you? What do you think?

We value your feedback and use it to continuously improve our products.A huge thank you in advance for sharing your feedback with us.

composition

composition

Outer shell: 100.0% Polyurethane; Bladder: 30.0% Polyester, 70.0% Latex Styrene Butadiene Rubber; Inside shell - Main fabric: 100.0% Polyester

Tips for storage and maintenance

DO NOT WASH.

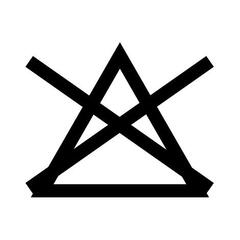

BLEACHING EXCLUDED.

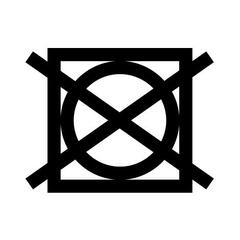

DO NOT TUMBLE DRY.

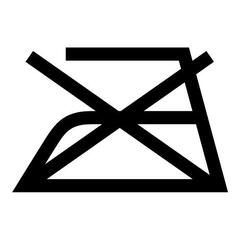

DO NOT IRON.

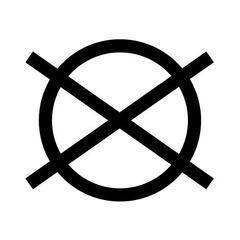

DO NOT DRY CLEAN.

Storage tips

Do not completely deflate the ball because this will damage the thermobonded panels and reduce the ball's life span and technical properties.<br /> After use, store your ball in a dry and ventilated place.

Restrictions on use

Do not completely deflate or crush.

TESTS AND WARRANTY

Test product

Compliant with international football federations' most stringent standards.Certified to FIFA Quality Pro standards.

Warranty

2 Years

Agree by

Complies with FIFA Quality Pro standards, the most rigorous standards for football designs.